DIAGNOSE. REPAIR. COMPARE.

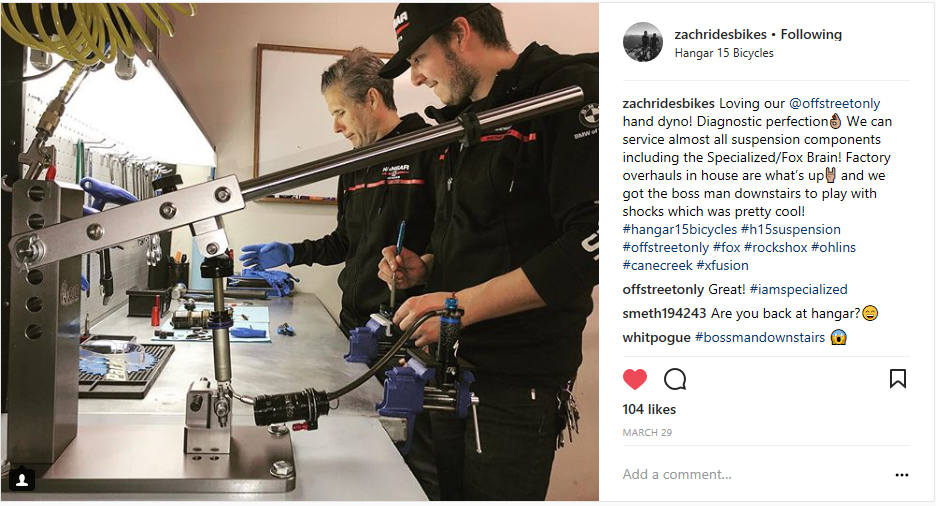

Since the mainstream introduction of front and rear suspension on mountain bikes in the mid 1990s, there has been a consistent challenge for companies to produce truly reliable and durable product while meeting performance goals, weight expectations, and size requirements . Suspension components on mountain bikes have anywhere from 30-150 parts and must seal air and oil through broad ranges of temperature, speed, and environmental conditions. Based on these facts, suspension components simply fail. Issues can arise due to assembly error, design flaws, employee turnover in critical positions, parts out of specification, and various other reasons. While all companies have their own processes and procedures for ensuring product leaves their factory as intended, nothing is 100%. Issues can arise immediately or happen over time. Depending on the rider and/or the bike, issues can not always be quickly identified without a closer inspection. This is where a solid fork and shock hand dyno will greatly help.

Easily and safely check travel and damper adjustments are working correctly.

DIAGNOSE

With a solid proper hand dyno, a technician can isolate the product and run through a variety of simple tests. They can generally diagnose, depending on experience, most failure issues.

Here are a few sample issues that a hand dyno can detect:

Low speed oil bleeding of a lock-out or high-threshold compression circuit

IFP gas loss or undercharged

Gas mixture with the damper oil

Incorrect IFP position

Broken adjuster parts

Loose piston, piston bolts, and other internal parts

Cracked or permanently deformed shims

Low or high oil fill

Debris in oil causing intermitent damping circuit failure

Shuttling caused by slow or leaking checks, loose piston glide rings, and related part design and quality issues

There is also a huge benefit in showing consumers a product’s performance on a hand dyno. They can see for themselves whether or not something is wrong, and if so, they will have greater faith in the technician’s abilities. In the end, everyone becomes more educated!

Safe and simple air sleeve removal and installation.

REPAIR

It is Off Street Only's firm belief that any repair or rebuild of any suspension component is always suspect unless properly checked over with at least a hand dyno. This quick test also applies to brand new product out of the box or recently received from authorized service centers. It is critical to be able to run through a standard full travel and adjuster range test at varying speeds to ensure the component is ready, working, and safe to put on a bike and charge trails.

Hand dynos also offer increased safety during the diagnosing and repair process.

Using a shock hand dyno is safer for removing and installing air sleeves.

Using a fork hand dyno is much safer for the technician when diagnosing and checking repairs on forks versus the extremely dangerous, accident waiting to happen, methods that are commonly used by even the most experienced engineer and technician!

Back-to-back product testing can be done safely in seconds.

COMPARE

Comparing a brand new component with a used compnonent or similar components with different tunes will drastically help broaden a technician’s understanding of a product’s design and their ability to work on it. Additionally, side by side comparisons of like products from different companies will showcase variances in friction, damping adjuster range and resolution, air spring curves and overall feel of quality and performance.

Taking this all a step further, having a hand dyno on the sales floor of a bike shop can be a key tool in engaging and educating consumers on suspension components and the different offerings by all the companies. While a test ride is ideal, this is not always possible. Depending on how the sales floor is organized, it might be too difficult to push on more than one bike. Having a small suspension test spot, the hand dyno can help educate the consumer as they work to choose what can be considered the most critical components on a mountain bike. The experience will also likely leave the consumer with greater respect for the staff and shop!

Off Street Only would also like to see media begin to incorporate hand dyno analysis and comparisions along with their field testing when performing suspension fork and shock reviews. While it certainly does happen, suspension components should not be designed to have a great showroom feel. However, adjusters should move smoothly and have positive detents and clicks when applicable. Low speed damper and chassis friction should also be clearly analyzed both on and off the bike. And in the end, it is just too easy to have a shootout of product and be able to throw each on the dyno and test back-to-back in a matter of seconds.